The Company

In 2000, we established our manufacturing facility in North China. Since then we have been manufacturing quality freeze dryers and lyophilizers.

Over the past tens years, Vekuma engaged in the design, produce and service all categories of freeze drying equipment. We close cooperate with our users, create feasible solutions to meet their specific requirement.

We continuously seek to improve the quality of our machines, the services of our offerings, and the strength of our solutions.

Our Products

Laboratory Freeze Dryer

For research laboratories and universities, to perform lab R+D and samples preservation.

Pilot Freeze Dryer

For lab R+D, drying cycle development, process optimization and small diagnostics production.

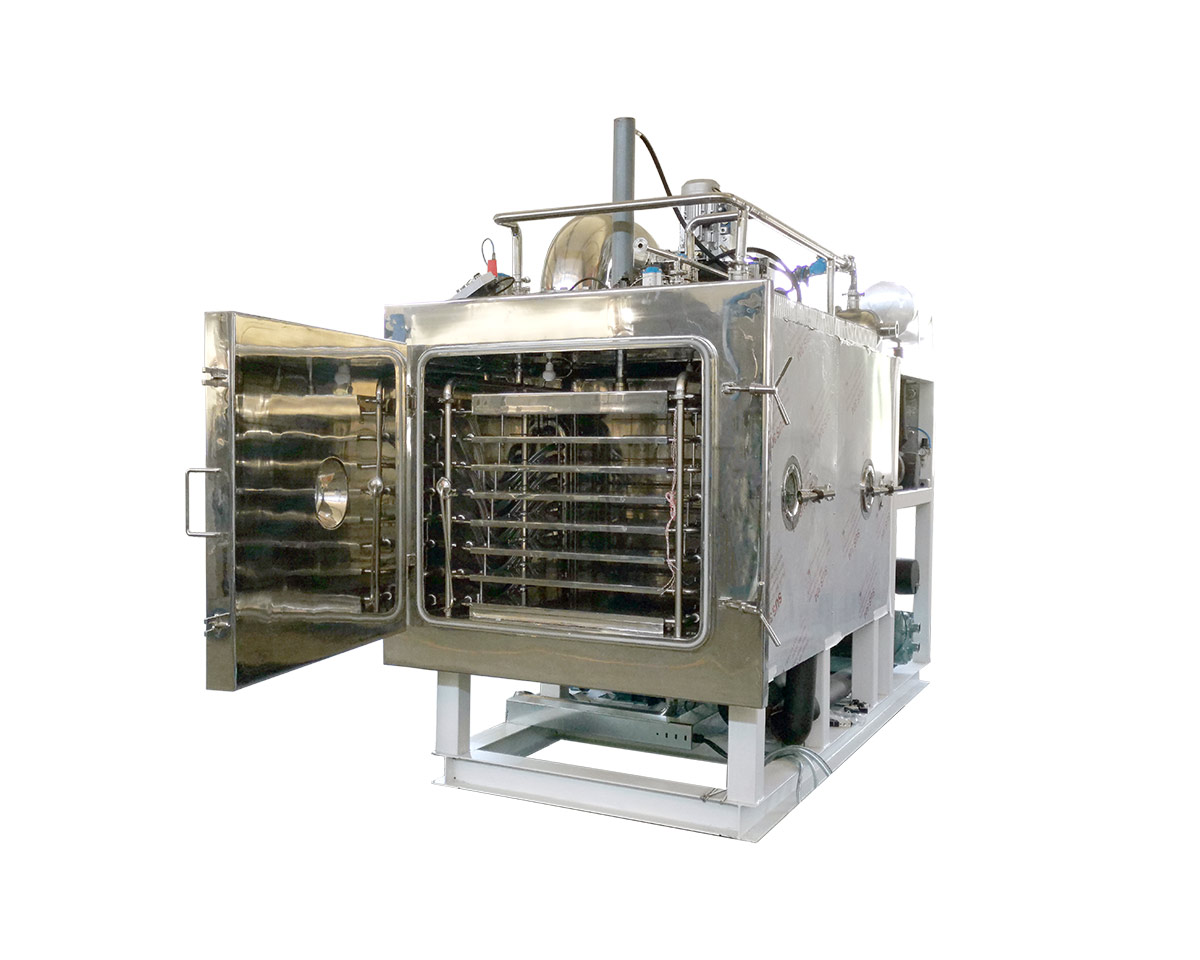

Production Freeze Dryer

For commercial and industrial large-scale production.

“Vacuum freeze drying/Lyophilization is the only method to deliver stable, biologically active products with a long shelf life!”

Vacuum Freeze Drying

Freeze drying also called lyophilization in pharmaceutical area, is a low temperature dehydration process, typically use to preserve perishable materials or make the material more convenient for storage.

Freeze drying removes water by use of sublimation technology. Freezing the material, and then reduce its surrounding pressure, the water in material is extracted out by vapor form (during freeze drying, frozen water sublime directly from solid phase to gas, skip the liquid phase). Mainly, freeze dry includes three steps: